Design and engineering solutions for established manufacturers and entrepreneurs since 1999

Affordable 3D printing service

Fast and accurate

Reverse engineering of existing parts

High surface quality reproductions

Batch runs

IP rated rugged enclosures developed to house third party electronics.

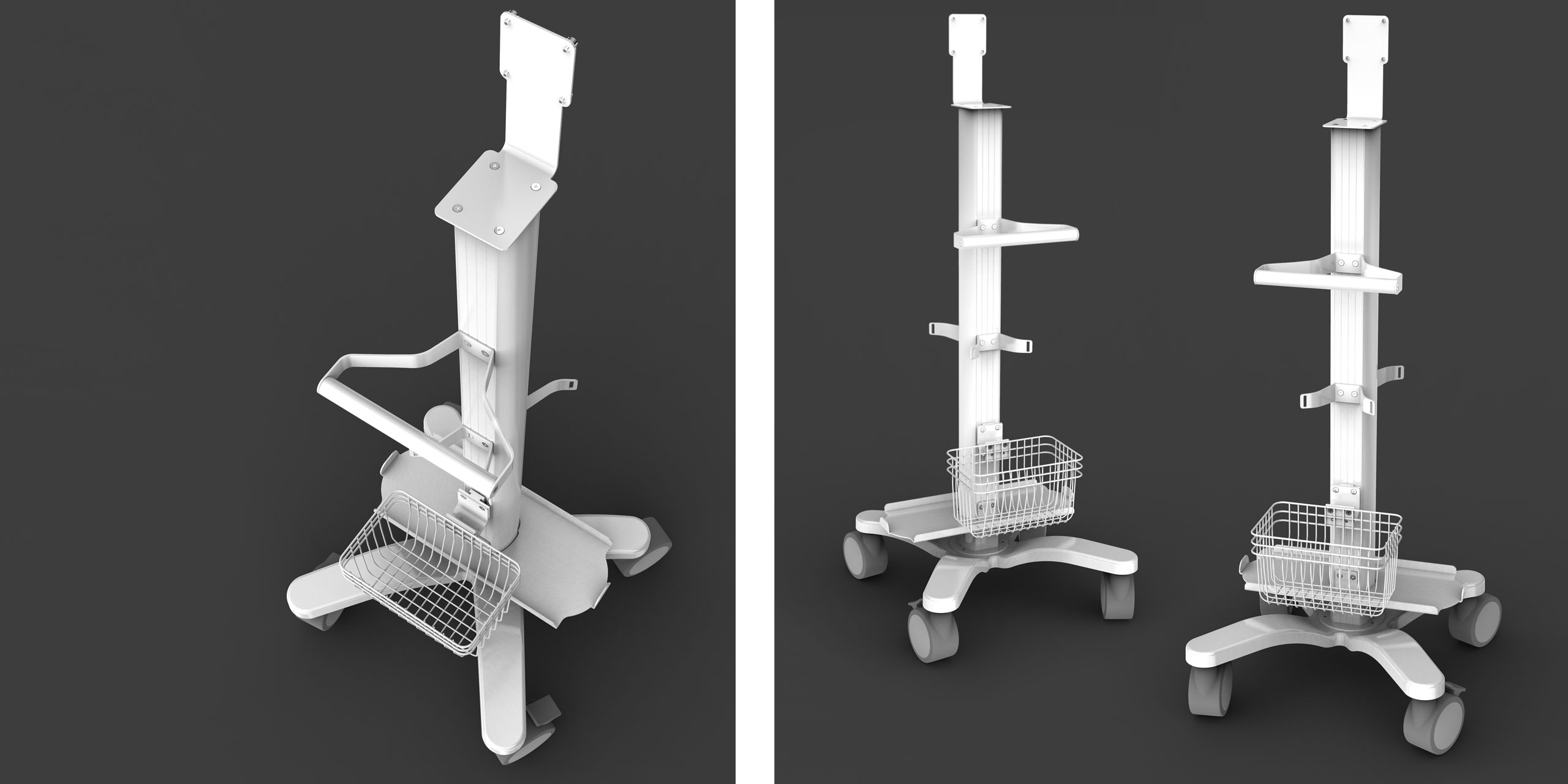

Equipment mounting solutions for the

hospital environment.

- Sheet metal

- Cast Aluminium

- Extrusions

- Laser and water-jet plastic

- Rapid prototyped plastic

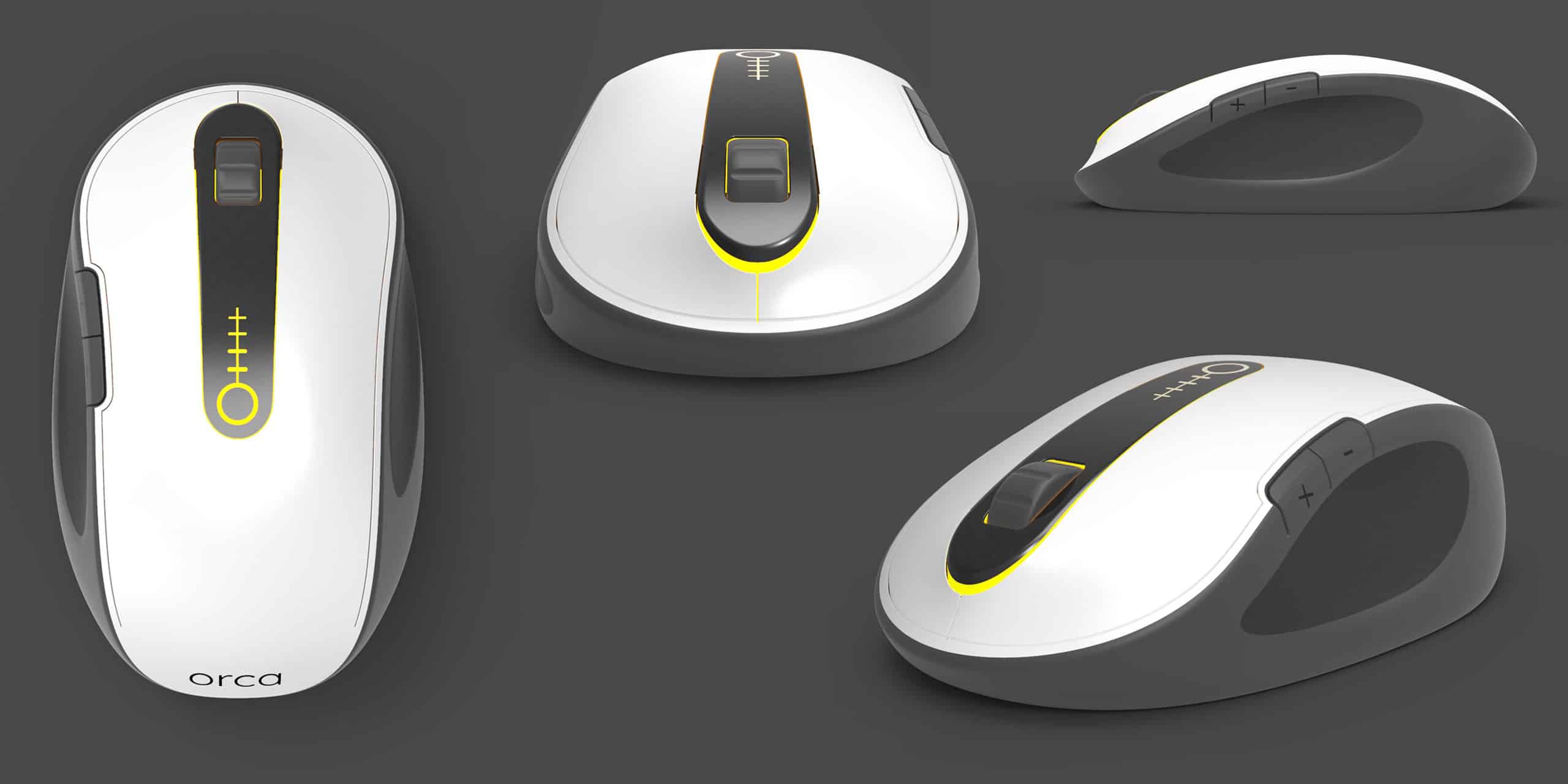

We have great experience developing consumer electronics and audio products for our clients.

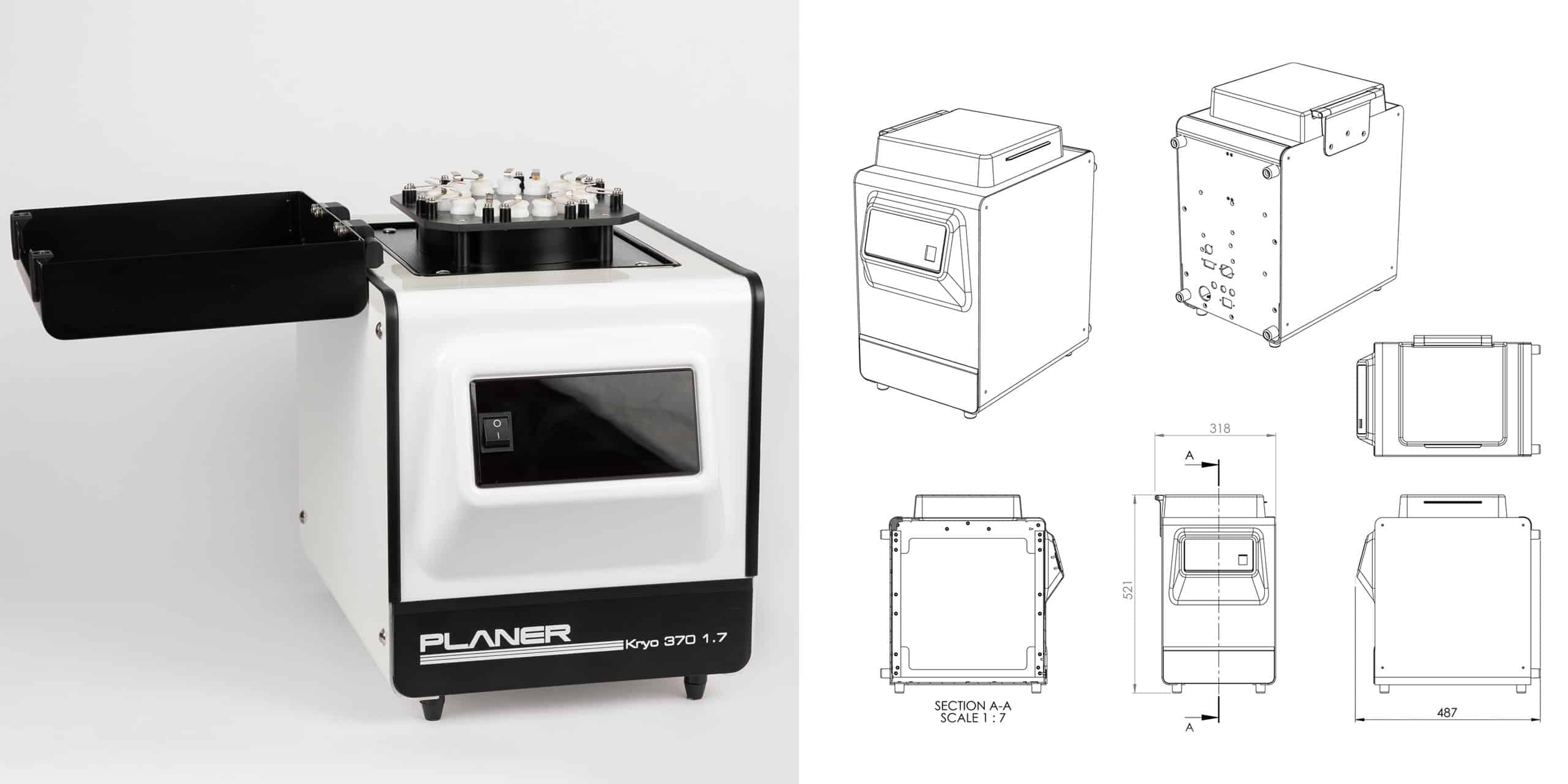

Laboratory equipment design for medical and scientific research.

Attractive product options can

be explored quickly alongside

physical 3D prototypes.

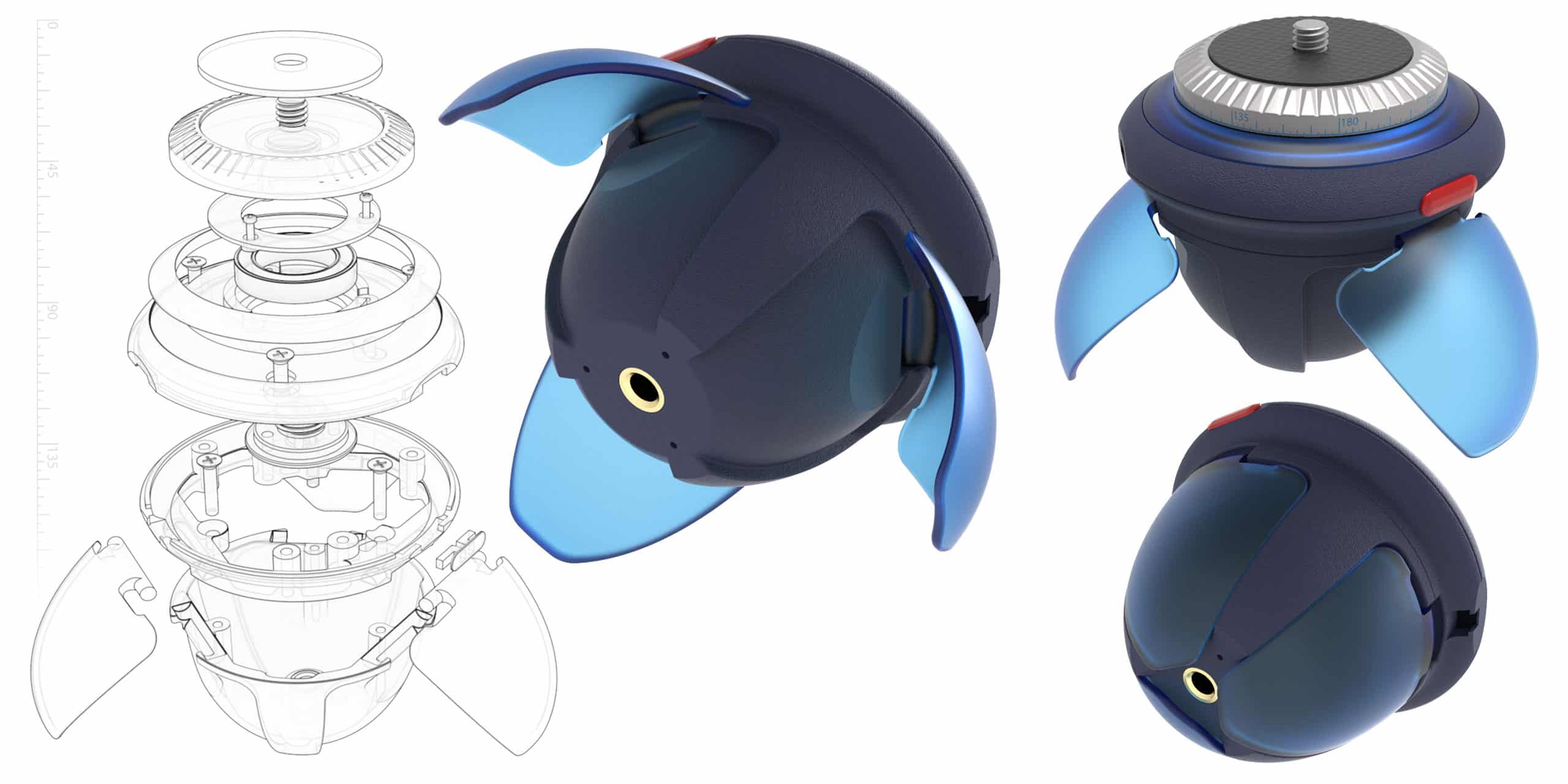

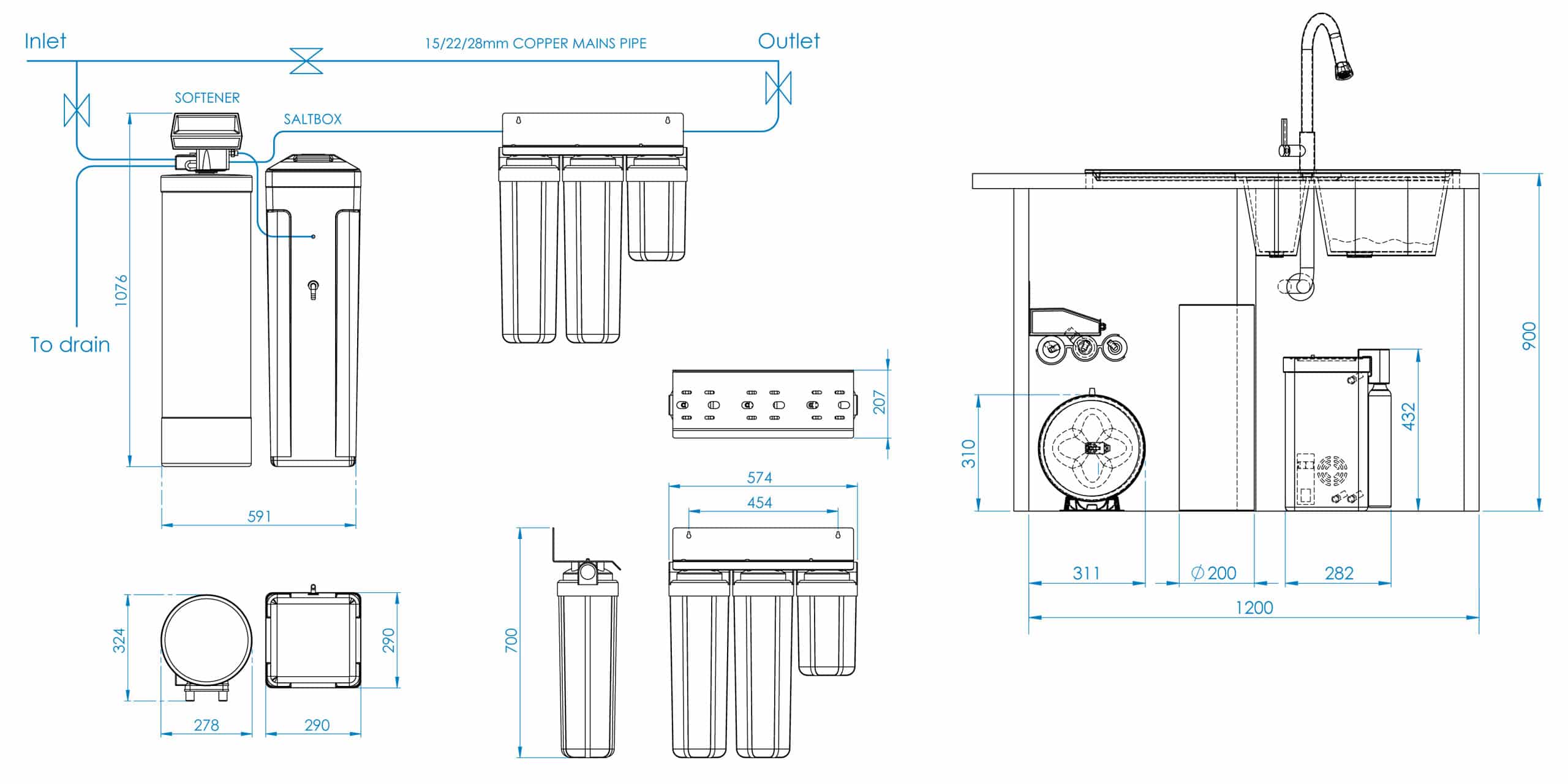

Sheet metal fabrication, Aluminium extrusions, CNC machining.

Complex mechanical enclosures which integrate custom and 3rd party electronics

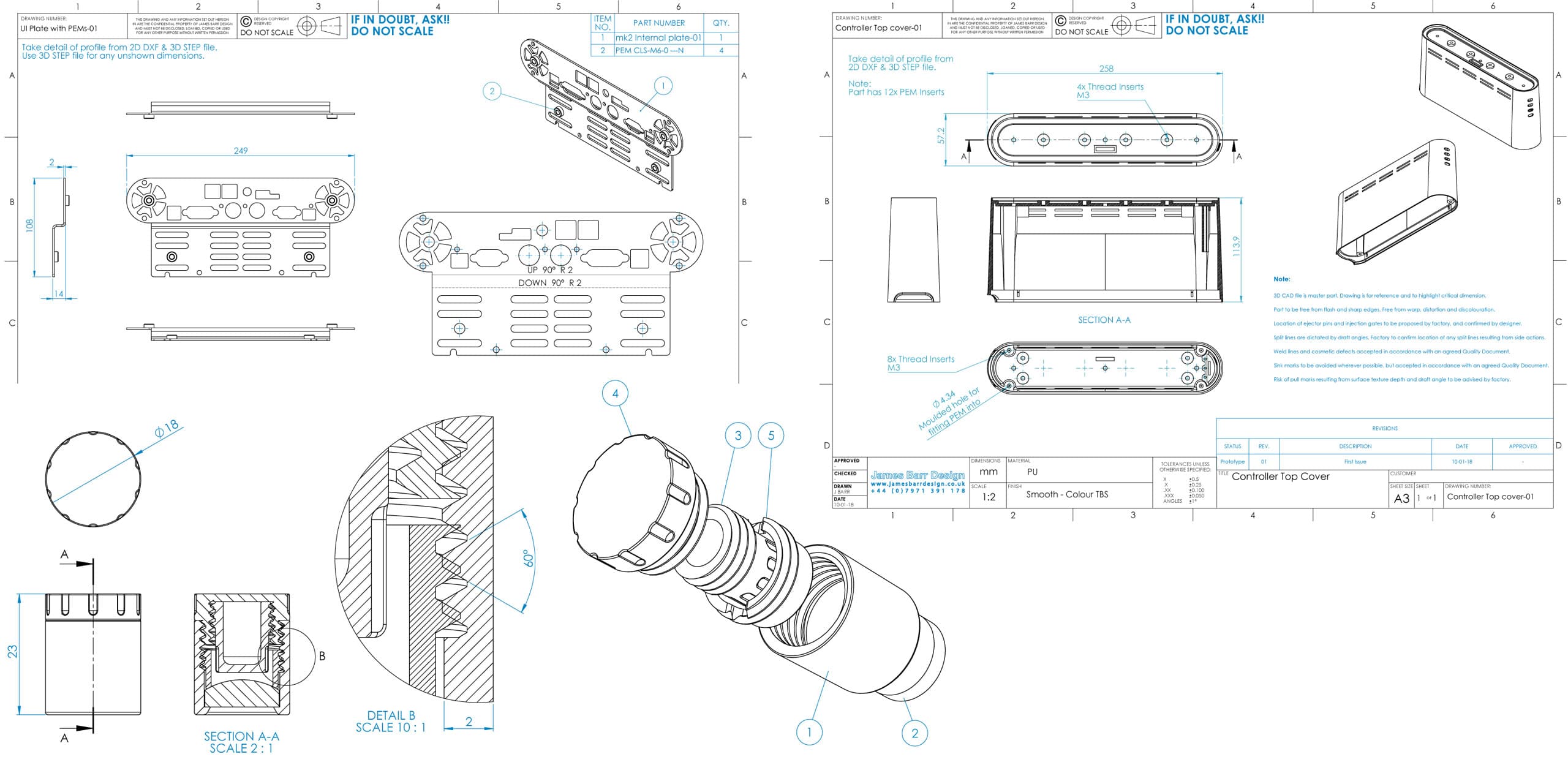

Revision control, critical dimensions, BOMs, material specification, tolerances.

Sheet metal internal structures with cosmetic external cladding. Integration of electronic hardware.

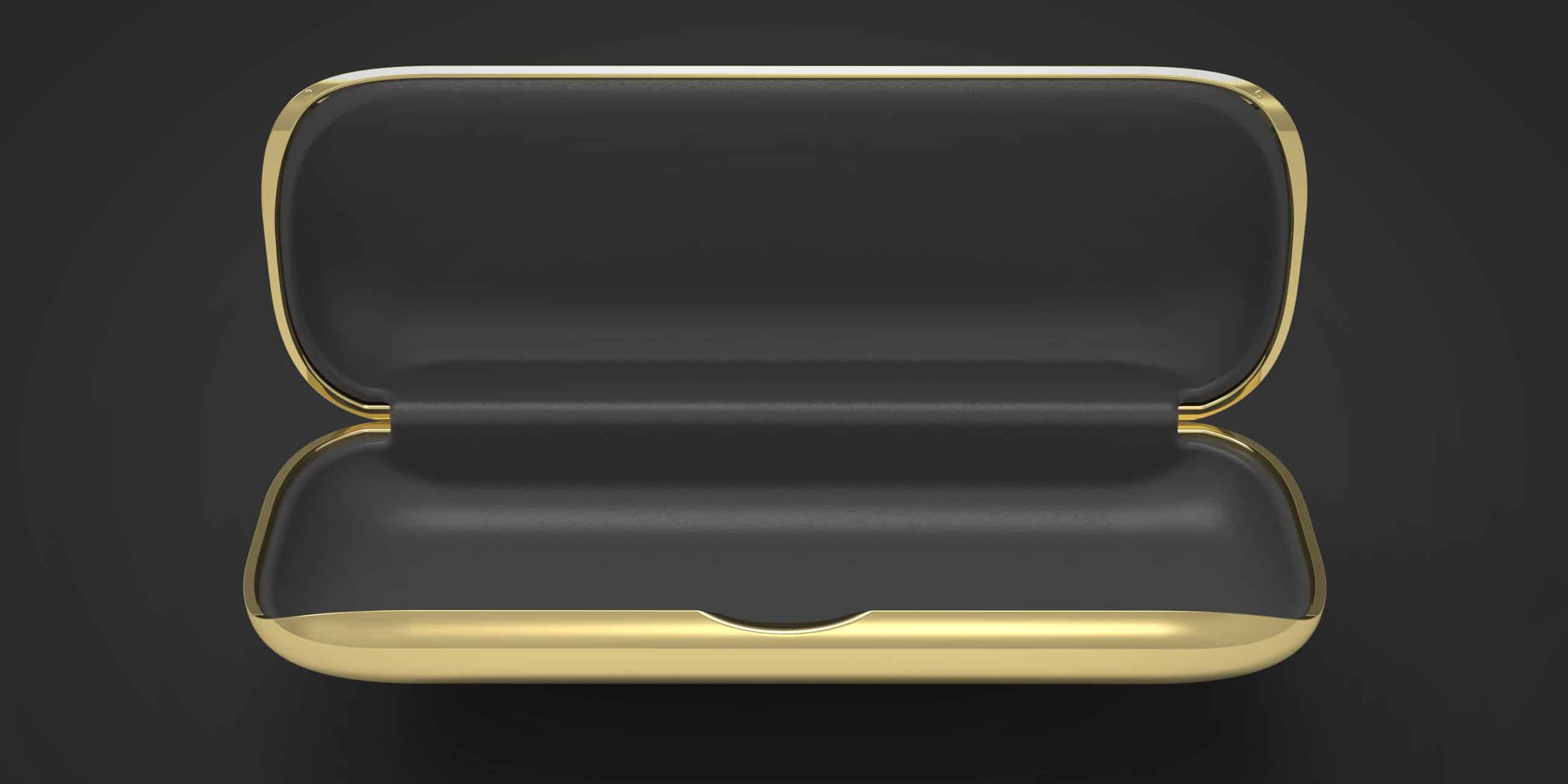

Aesthetic concept designs are explored using premium materials and refined finishing techniques.

Product development, graphic design, prototyping and marketing visuals.

Injection moulded parts for a range of applications and industries including medical, FMCG and consumer electronics.

For reference documentation and marketing

Respiratory rehabilitation device which was grant funded by InnovateUK.

James Barr Design have had great success writing grant applications for our clients.

SMEs

Working with SMEs and established businesses who seek professional assistance with engineering and new product development. We can work as an effective addition to your permanent team. With many years commercial experience we can provide an exceptional, flexible, R&D (Research and development) service.

Capable of tackling a broad range of projects and scientific uncertainties; IP rated enclosures for electronics, ergonomic forms and mechanical engineering.

[Click for FAQs]

- Medical diagnostics

- Signage and wayfinding

- Information and payment kiosks

- Military equipment

- FMCG and structural packaging

- AV and consumer electronics

- Industrial electronics enclosures

- Hospital equipment

Entrepreneurs

Guiding you, an entrepreneur with an idea, through the steps needed to bring a product to market. With the benefit of nearly 25 years industry experience we can work with you to create the perfect product.

We specialise in problem solving, generating ideas and creating products which are functional, attractive and economically viable.

[Click for FAQs]

- Lifestyle products

- Mother and baby

- DIY and industrial tools

- Sporting goods

- Scientific and research

- Living aids and healthcare

- Toys and games

- Education

Advice for Entrepreneurs

About us

Company owner James Barr BSc (Hons) established a limited company in 2014 to work directly with clients both big and small. With a network of trusted manufacturing partners James Barr Design has great experience prototyping and manufacturing finished products.

James has been a consultant designer since 1999, working in a wide range of industries as both a consultant and in-house senior designer. Consultancy work requires the ability to research and quickly understand any products unique challenges and opportunities. Running in-house design teams requires great attention to detail for all aspects of a product launch including quality control, graphic design and packaging.

We specialise in CAD product design in Surrey, London, Kent and Sussex but do take on clients across the UK and Europe. Communication is key for remote working; We make sure clients are regularly kept updated with progress through zoom meetings, phone calls and emails.

Research and development (R&D), and new product development (NPD) involve some iterative design work to solve practical, technological or scientific uncertainties. Through experience we work with our clients to make sure the service we offer is as effective and efficient as possible.

Testimonials

Experience and technology

Having worked since 1999 in product design and engineering we have a wealth of experience to draw from both in terms of manufacturing knowledge and aesthetics. We use the very latest 3D CAD systems (SolidWorks), and have in-house 3D printing and 3D scanning technologies.

Investment in rapid prototyping equipment and industry standard software means our design process is very efficient. We can develop concepts in a few days and in some cases can produce a working prototype in under an hour!.

We use the very latest version of SolidWorks to generate our 3D parts, assemblies and 2D control drawings. It can import legacy data from most common 3D file formats for reuse or as a reference.

SolidWorks is the industry standard software for designing and releasing information to prototyping and manufacturing partners. The 3D designs we create can easily be used by manufacturers for mass production.

Evaluation of physical prototypes using 3D scanning and in-house prototyping allows for fast iterative testing of components.

We have the in-house ability to create very large 3D printed prototypes up to 500x500x500mm. Printed models can be very precise holding dimensions less than 0.05mm.

Our software allows us to create both very precise geometric forms for engineering projects and smoother ‘organic’ shapes more suitable for ergonomic applications.

Past projects

Over the last 25 years we’ve worked on an incredible range of projects, including:

Access control, nuclear inspection, sporting goods, fragrance devices, (medical) disposable diagnostic, laboratory equipment, oil industry, construction equipment, DIY, marine safety, mother and baby, toys, martial arts, military tripods, high-end audio products (amps), loudspeakers for consumer and retail market, AV systems (home automation), FMCG, packaging, transport, education, furniture, medical equipment handling, medical patient entertainment, consumer electronics, lifestyle products, sustainable products, security, process containment, industrial machinery, healthcare – rehabilitation devices, marketing and promotion, barcode scanning, industrial work-desks, signage, point of sale, digital wayfinding, security, motorsport advertising, car care, dental PPE, flight simulation, household goods, exhibition planning, wound care, luggage, petro-chemical, building & associated trades, cryogenics, industrial 3D-scanning, plush toys, airsoft, mountain bike accessories, home security, promotional gifts, gaming accessories, keyboards, pet care, dental, souvenir vending machines, kitchenware, water purifiers, luggage, building site safety, building site maintenance, food delivery, motion detection sensors, boxing pads, drinks bottle (with integrated electronics), candles, commemorative coins and plaques, food packaging and in-store displays, hotel reception entry-phone, binaural loudspeaker, microphone stands, custom wristwatch, curtain fixtures, tech-enabled food and drink delivery, architectural model, punchbags, sunglasses, tablet PC enclosures, Wine glass accessories, PC/power supply accessories, remote controls, plastic seating, festival structures, custom aerodynamic wind tunnel, custom car interior panels, jewellery (bespoke rings), cosmetics, water-filtration, bakery equipment, shop mannequins, drone (military applications), golf clubs, motion sensors, air suspension, custom car parts, remote control car parts, architectural models, POS payment terminals, historic reproductions (mechanical and ornamental), alcoholic beverage packaging, phone cases, aerospace maintenance…

Contact us to discuss your idea! We’re always happy to take your call, discuss the design process and whatever you need help with.